OUR STORY

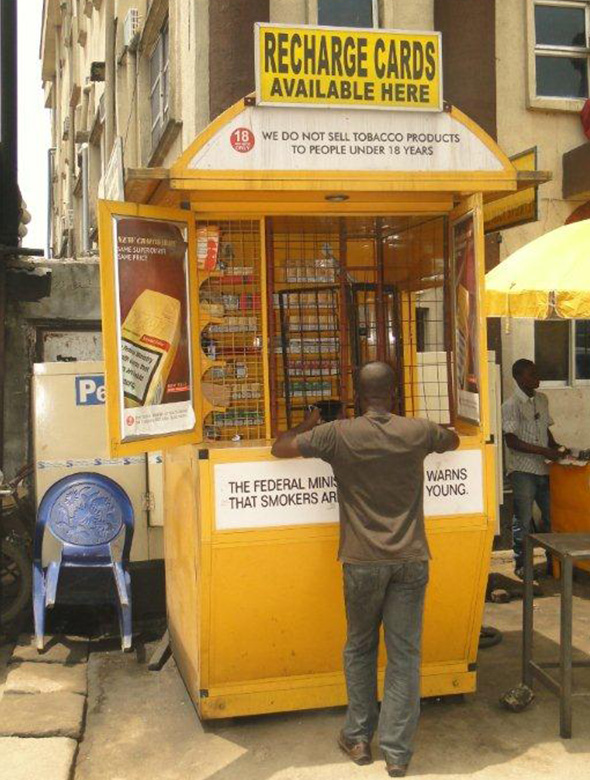

POMAT COMPOSITES manufactures fiberglass products for use in businesses and industries throughout Africa, and beyond. Our fiberglass kiosks and other modular products are used anywhere there’s a need for durable, weatherproof structures.

With roots in West Africa, our reach extends throughout the continent and beyond. Our team of experienced technical staff and operators, engineers, technicians, and operations managers work to ensure that every product ordered is built precisely to a client’s specifications.

To keep pace with ever-changing infrastructure and business needs, we offer an end-to-end solution from concept and design through engineering and construction. Using lean manufacturing principles, eliminating waste and anything that doesn’t add value, are what allows us to keep our pricing competitive and our products delivered on time.